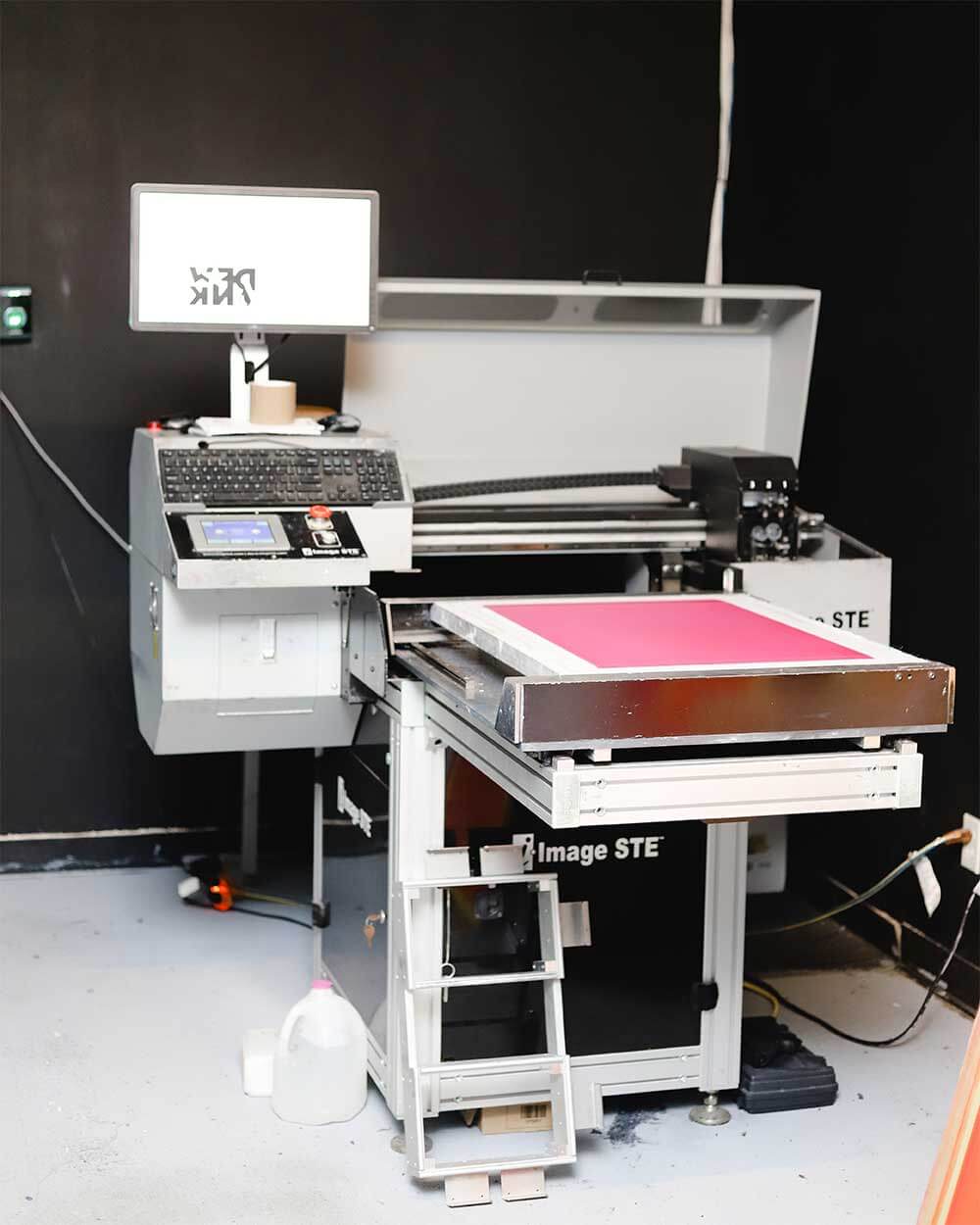

The Digital Squeegee

Full color prints on a screen printed white underbase at 400 shirts per hour!

Combining high-resolution digital printing with the speed and cost savings of screen printing to offer you the...

Read More